Electronics Consulting

Expertise in Electronics Design and Multi-Layer PCB Layouts

We specialise in creating custom electronic solutions, including bespoke time-of-flight and stereo-vision cameras, wireless sensors, and custom PCBs. Utilising Altium in-house, our IPC-certified associates are proficient with most other design packages.

Our engineers are experienced in Design for Manufacture methodologies, employing techniques to minimise component and build costs while maximising yield and throughput in volume production.

To reduce prototyping timeframes, we have in-house solder reflow facilities for small-volume surface-mount component placement

Time of Flight Camera

Peacock Technology has a long-standing history of developing bespoke 3D imaging cameras using Time of Flight (TOF) chipsets. We initially created cameras utilizing chipsets from TOF pioneer PMD Technologies at a time when off-the-shelf TOF cameras for industrial applications were unavailable.

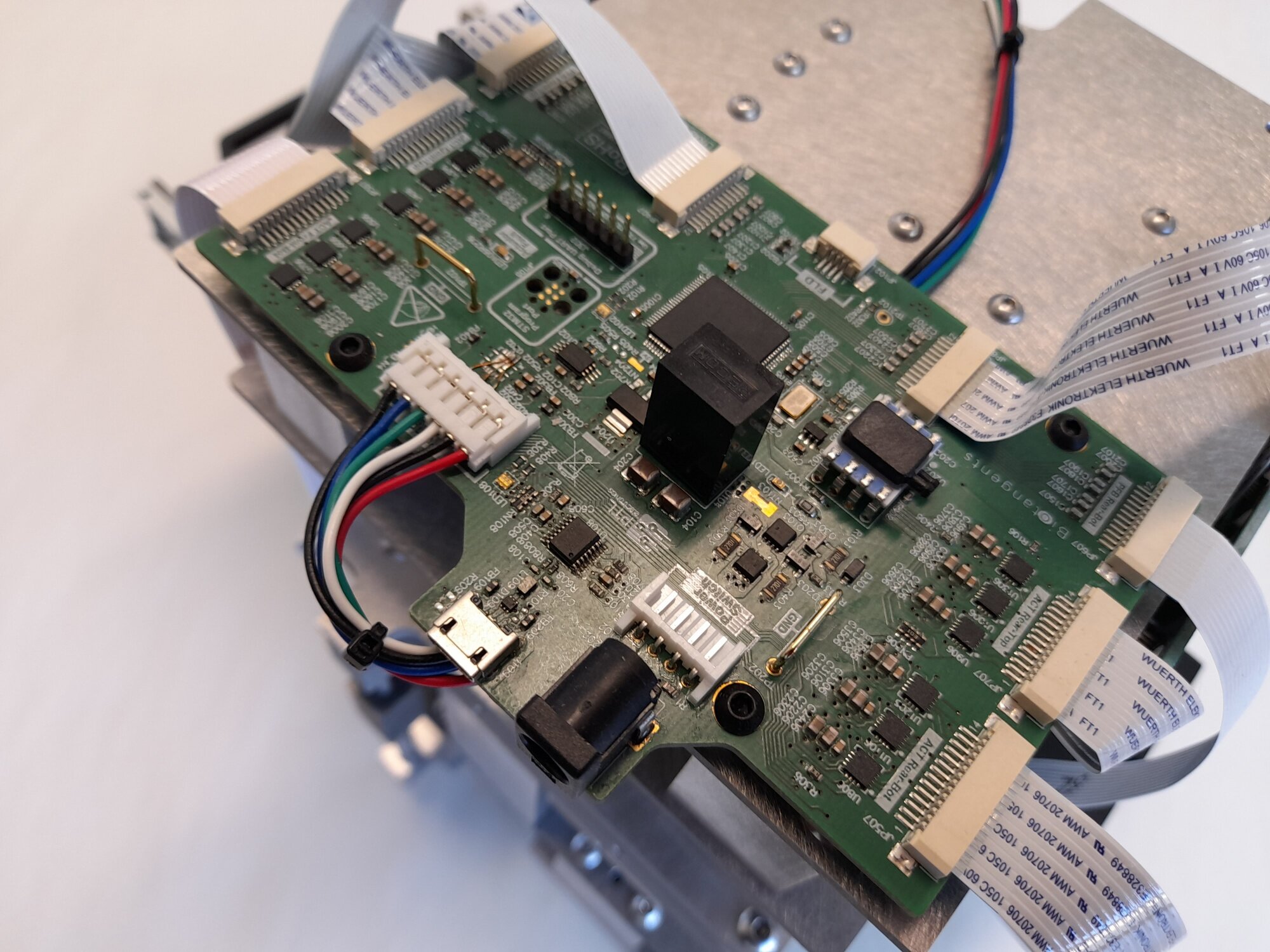

More recently, we have designed a camera around the Texas Instruments OPT8241, incorporating a Freescale i.MX6 processor for control. By leveraging the capabilities of the i.MX6, we embed full image processing applications directly on the board, transforming it from just a camera into an intelligent sensor.

Our cameras have found numerous applications in the AgTech industry, including robotic milking machines and measuring the size of pigs.

Cow Pedometer

As farm sizes increase, farmers often struggle to monitor livestock welfare effectively, which can lead to significant financial implications if preventable diseases go undetected. We addressed this challenge for our client by creating a wireless sensor system capable of monitoring animals and automatically detecting specific diseases and welfare issues.

We designed and developed a robust, low-cost sensor tag that records livestock behaviours and wirelessly transmits the data to farm computers. This platform enabled our client to build upon it and automatically detect conditions of interest.

Peacock Technology led the client through prototype development and into volume manufacturing. They now have the leading condition monitoring system in their class, achieving global sales and receiving recognition for the product, including the prestigious John Logie Baird Award for Innovation.

Embedded Microfluidic Control System

Our client was developing a next-generation livestock disease diagnosis system utilising a complex microfluidic process and needed a market-ready device. We collaborated closely with them to create a device featuring an embedded microcontroller system based on the STM32, controlling a large array of actuators and motors through 12 channels of Texas Instruments H-bridge drivers.

The system required precise temperature, pressure, and fluid level sensing. System-level control was provided through an embedded USB interface, and the software was developed in C. Our comprehensive solution enabled the client to bring their innovative product to market successfully.

Underwater Lighting

Our client, a global leader in aquaculture products, needed a high-output, high-efficiency underwater lighting system for environmental control in fish farms. The system required flexible user control and built-in intelligence to adapt to various environmental conditions and user profiles.

We developed a device utilising state-of-the-art high-power LEDs from Cree and ultra-compact dimming technology from ST Microelectronics.

The embedded system was based on an STM32 microcontroller with CANbus communications, enabling long-range, multi-master, multi-drop control.

Wind Turbine Control System

A new control system was required to replace an obsolete one in a wind turbine design. The solution needed to ensure the safe operation of the turbine while providing new features such as remote access and data logging.

Peacock Technology developed a replacement control system using an Omron PLC. This system monitors wind speed, wind direction, and blade rotation speed, utilising a PID loop to adjust the pitch of the turbine blades and maintain optimal rotation speeds for electricity generation. Remote access is provided over GPRS, enabling monitoring of the turbines and remote updates for new control versions.

Our client has successfully retrofitted the control system into existing wind turbines and is deploying it across their Scottish network of wind farms. This advancement is crucial for improving sustainable production. If a human expert can identify a problem, we can train our algorithms to detect it too.